Production process of neodymium magnets are similar as a construction brick sintered in a high temperature stove. With high temperatures treatment, it makes the brick solid and strong.

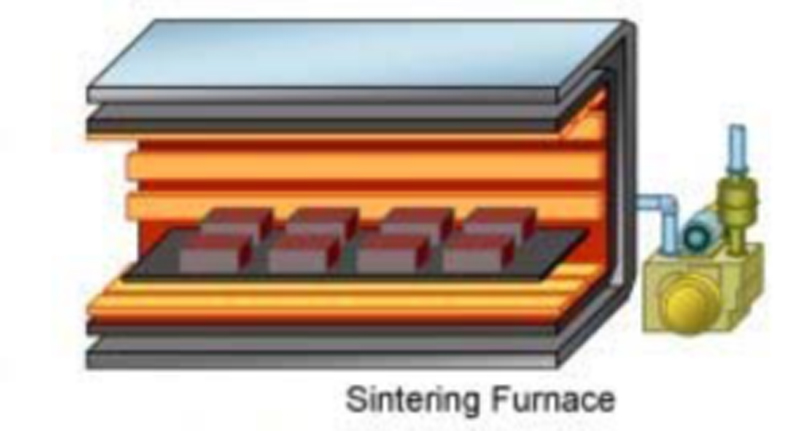

The main production process for neodymium magnets are sintering process, that’s why we call it sintering neodymium magnets. The main ingredients are neodymium(Nd 32%), Ferrum(Fe 64%) and Boron(B 1%), that’s why we also call neodymium magnets to be NdFeB magnets. The sintering process are protected with inert gas(such as nitrogen, argon or helium gas) in the vacuum furnace, as magnetic particles are small as 4 microns, easy flammable, if exposed in the air, easy to be oxidized and catch fire, so we protect them with inert gas during productions, and it will take around 48 hours in the sintering stove. Only after sintering we could achieve a solid and strong magnet ingots.

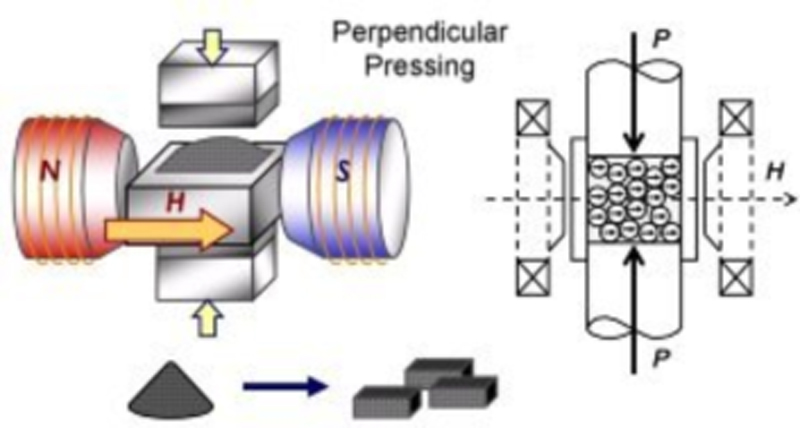

What is magnet ingots? We have magnetic particles that have been pressed in a mold or tooling, if you require disc magnet, then we have disc mold, if you require block magnet, then we have bock mold, the magnetic particles are pressed in the steel mold and come out magnet ingots, then we have these magnet ingots heat treated in a sintering furnace to achieve a solid state. The density of the ingots prior to sintering is about 50% of true density, but after sintering, the true density is 100%. Neodymium magnet density is 0.0075 gram per cubic millimeters. Through this process the magnet ingots' measurement shrink by about 70%-80% and their volume is reduced by about 50%. Aging the magnet ingots after sintering to adjusts the properties of the metals.

Basic magnetic properties are set after the sintering and aging processes are completed.

Key magnetic properties measurements including remanence flux density, coercivity, and maximum energy product are recorded in file. Only those magnets that pass the inspection will be sent to subsequent processes for further machining, plating, magnetizing and make final assembly, etc.

Normally we achieve customer tolerance requirements by machining, grinding and abrasives, such as the magnet slicing will be like the CNC machining, etc. we customize special machines to make different processing on magnets. There are a lot of work to be done to meet customer special requirements.

Post time: Jun-14-2022